Hi Volt Sil-A-Blend® 200

HIGH-VOLTAGE LEAD WIRE

Ratings/Approvals:

- 200°C – 7.5KV – UL Style 3576

- 200°C – 10KV – UL Style 3573

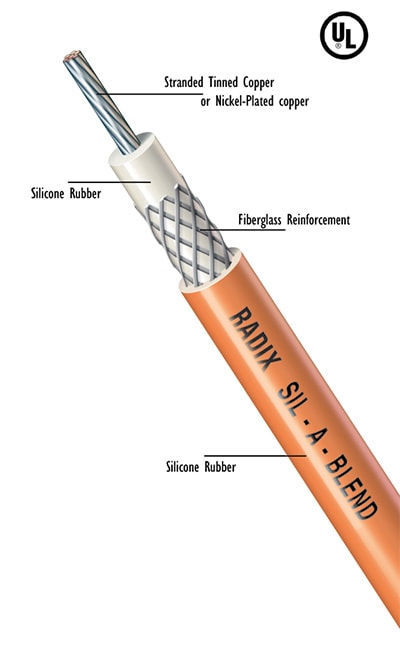

Construction:

- Conductors

- 22 AWG – 12 AWG

- Stranded tinned copper or nickel-plated copper

(Other conductor materials available)

- Insulating System

- Composite Extruded Silicone Rubber with intermediate fiberglass reinforcement

- Standard Color Coding

- Available in Colors

Characteristics:

- Outperforms Braided Silicone products

- Smaller OD, lighter weight, tighter bend radius

- Durable outer jacket

- Eliminates braid fraying, flowering, and shrink back

- Virtually eliminates skin irritation

- Significantly reduces airborne fiberglass contaminants traditionally found in high volume processing

- Superior flexibility

- Color stable at elevated temperatures

- LSZH: Low smoke, zero halogen

- Specially formulated outer silicone jacket greatly enhances abrasion resistance

- Silicone formulations suitable for UV, ozone, moisture exposure

- Suitable for varnish dip and bake applications

- Not suited for immersed applications

- Suitable for applications to -60°C

SPECIFICATIONS

Hi Volt Sil-A-Blend® 200

HIGH-VOLTAGE LEAD WIRE

Download Hi Volt Sil-A-Blend® 200 Specs

Sil-A-Blend® 200C/7.5KV

| Part No. | Temp Rating | Voltage Rating | Awg. Size | # Strands | Outer Dia. inches | Outer Dia. mm | Wgt (lbs/Mft) | Wgt (kg/km) | Min. Bend Radius (in) | UL | CSA |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NDA22P007 | 200C | 7500V | 22 NPC 2% | 7 | 0.100 | 2.54 | 6.62 | 9.85 | 0.80 | 3576 | N/A |

| NDA20P007 | 200C | 7500V | 20 NPC 2% | 7 | 0.110 | 2.79 | 8.36 | 12.44 | 0.88 | 3576 | N/A |

| NDA18T007 | 200C | 7500V | 18 | 7 | 0.119 | 3.02 | 10.75 | 16.00 | 0.95 | 3576 | N/A |

| NDA16T007 | 200C | 7500V | 16 | 7 | 0.130 | 3.30 | 14.39 | 21.42 | 1.04 | 3576 | N/A |

| NDA14T007 | 200C | 7500V | 14 | 7 | 0.142 | 3.61 | 19.07 | 28.38 | 1.14 | 3576 | N/A |

| NDA12T019 | 200C | 7500V | 12 | 19 | 0.160 | 4.06 | 28.59 | 42.55 | 1.28 | 3576 | N/A |

Sil-A-Blend® 200C/10KV

| Part No. | Temp Rating | Voltage Rating | Awg. Size | # Strands | Outer Dia. inches | Outer Dia. mm | Wgt (lbs/Mft) | Wgt (kg/km) | Min. Bend Radius (in) | UL | CSA |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NEA22P007 | 200C | 10000V | 22 NPC 2% | 7 | 0.120 | 3.05 | 8.02 | 11.94 | 0.96 | 3573 | N/A |

| NEA20P007 | 200C | 10000V | 20 NPC 2% | 7 | 0.126 | 3.20 | 10.16 | 15.12 | 1.01 | 3573 | N/A |

| NEA18T007 | 200C | 10000V | 18 | 7 | 0.139 | 3.53 | 13.09 | 19.48 | 1.11 | 3573 | N/A |

| NEA16T007 | 200C | 10000V | 16 | 7 | 0.147 | 3.73 | 16.52 | 24.59 | 1.18 | 3573 | N/A |

| NEA14T007 | 200C | 10000V | 14 | 7 | 0.160 | 4.06 | 21.54 | 32.06 | 1.28 | 3573 | N/A |

Standard conductor: Tinned Copper or Nickel Plated Copper (2%) as designated

Consult factory for alternative conductor and stranding options.

All dimensions listed above are nominal

Compliance: UL Listed File No. E22244.