DuraFlex® 550

HIGH-TEMPERATURE WIRE

Ratings/Approvals:

- 550°C – 300 Volts – UL 5390 / CSA AWM I A/B FT1

- 550°C – 600 Volts – UL 5400 / CSA AWM I A/B FT1

- VW-1 Flame Rating

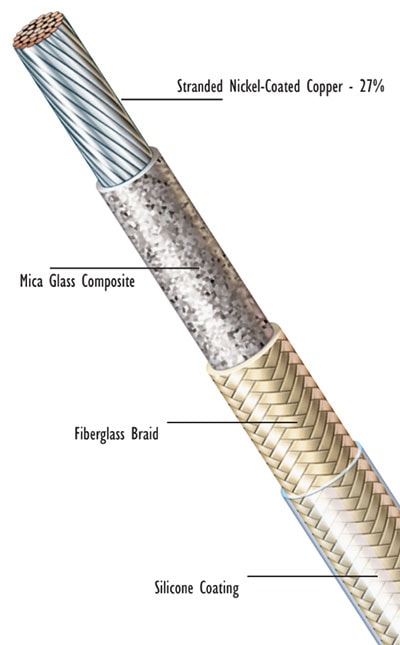

Construction:

- Conductors

- 24 AWG – 14 AWG (300 Volts)

- 22 AWG – 8 AWG (600c Volts)

- Stranded nickel-coated opper – 27%

(Other conductor materials available)

- Insulating System

- Mica glass composite

- Outer Covering

- Fiberglass braid with silicone coating

- Standard Color Coding

- White

- Colored Tracers

Characteristics:

- Outperforms UL 5128/5107 MGT products:

- Unique insulation system offers outstanding heat-aged flexibility for longer service life.

- Passes UL 2X mandrel test after heat aging UL 5128/5107 is 3X mandrel).

- Modified silicone jacket virtually eliminates dermatitisproblems associated with handling fiberglass and braid fray.

- 550°C temperature rating allows wire to be installed in extreme environments and reduces the cost of added thermal protection (glass sleeve, ceramic insulator, etc).

- Excellent cutting and stripping characteristics, making it ideal for high volume manufacturing and assembly.

- Provides dimensional consistency and uniformity.

- Resists braid pushback.

- Withstands mechanical abuse.

SPECIFICATIONS

DuraFlex® 550

HIGH-TEMPERATURE WIRE

DuraFlex® 550C/300V

| Part No. | Awg. Size | # Strands | Outer Dia. inches | Outer Dia. mm | Wgt. (lbs/Mft) | Wgt (kg/km) | Min. Bend Radius (in) | UL | CSA |

|---|---|---|---|---|---|---|---|---|---|

| DCS24C007 | 24 | 7 | 0.080 | 2.03 | 5 | 7.22 | 0.64 | 5390 | AWM I A/B FT1 |

| DCS22C007 | 22 | 7 | 0.087 | 2.21 | 6 | 8.86 | 0.70 | 5390 | AWM I A/B FT1 |

| DCS20C010 | 20 | 10 | 0.092 | 2.34 | 7 | 10.37 | 0.74 | 5390 | AWM I A/B FT1 |

| DCS18C016 | 18 | 16 | 0.104 | 2.64 | 10 | 15.30 | 0.83 | 5390 | AWM I A/B FT1 |

| DCS16C026 | 16 | 26 | 0.120 | 3.05 | 15 | 22.49 | 0.96 | 5390 | AWM I A/B FT1 |

| DCS14C041 | 14 | 41 | 0.130 | 3.30 | 20 | 29.69 | 1.04 | 5390 | AWM I A/B FT1 |

DuraFlex® 550C/600V

| Part No. | Awg. Size | # Strands | Outer Dia. inches | Outer Dia. mm | Wgt. (lbs/Mft) | Wgt (kg/km) | Min. Bend Radius (in) | UL | CSA |

|---|---|---|---|---|---|---|---|---|---|

| DDS22C007 | 22 | 7 | 0.098 | 2.49 | 8 | 12.38 | 0.78 | 5400 | AWM I A/B FT1 |

| DDS20C010 | 20 | 10 | 0.108 | 2.74 | 10 | 14.99 | 0.86 | 5400 | AWM I A/B FT1 |

| DDS18C016 | 18 | 16 | 0.124 | 3.15 | 13 | 19.26 | 0.99 | 5400 | AWM I A/B FT1 |

| DDS16C026 | 16 | 26 | 0.138 | 3.51 | 17 | 25.95 | 1.10 | 5400 | AWM I A/B FT1 |

| DDS14C041 | 14 | 41 | 0.158 | 4.01 | 24 | 36.24 | 1.26 | 5400 | AWM I A/B FT1 |

| DDS12C065 | 12 | 65 | 0.182 | 4.62 | 35 | 52.80 | 1.46 | 5400 | AWM I A/B FT1 |

| DDS10C105 | 10 | 105 | 0.212 | 5.38 | 52 | 77.64 | 1.70 | 5400 | AWM I A/B FT1 |

| DDS08C133 | 8 | 133 | 0.266 | 6.76 | 78 | 116.01 | 2.13 | 5400 | AWM I A/B FT1 |

Standard conductor: Nickel Coated Copper – 27%

Consult factory for alternative conductor and stranding options.