SRG-K

HIGH-TEMPERATURE CABLE

Ratings/Approvals:

- 200°C – 600 Volts

- Passes NEMA WC 3 Flame Propagation Test

- Passes the IEEE-383 (modified) 210,000 BTU/hr Vertical Cable Tray Flame Test

- Passes ICEA T-27-581 Water Absorption Test

- RoHS Compliant

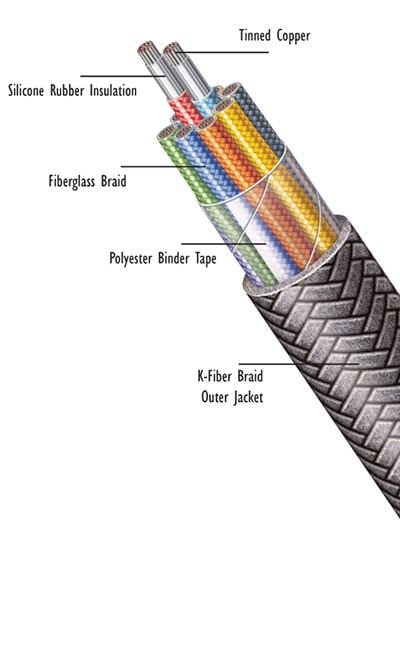

Construction:

- Conductors

- 22 AWG – 2 AWG

- Annealed tinned copper

- Insulating System

- Extruded silicone rubber with fiberglass braid cover over each insulated conductor. Braid treated with a moisture, heat and flame resistant finish for K-2 color coding (Unless specified) and abrasion resistance.

- Overall Binder Tapes

- Polyester

- Outer Covering

- Braided aramid K-fiber with a moisture, heat and flame resistant finish

- Standard Color

- Black (Colors available)

Characteristics:

- Silicone formulations suitable for UV, ozone, moisture exposure

- Fillers, where needed, are made with flame-impervious fibers with moisture-repellent finish

- Cable utilizes Radix “Torque Free” design. This eliminates memory found in traditional right-hand o left-hand twisted cables

- Binder tape is non-hydroscopic, non-wicking polyester.

- Suitable for applications to -60 ̊C

- Aramid K-fiber provides superior cut-through and abrasion resistance

- Non recommended for outdoor use

Applications:

- SRG-K is constructed for use in high temperature applications as a multiple conductor control cable where resistance to abrasion and mechanical abuse are desired. This cable is widely used in steel and glass plants, as well as high temperature locations near boilers, steam lines and chemical processing plants.

SPECIFICATIONS

SRG-K

HIGH-TEMPERATURE CABLE

SRG-K 150C/600V

| Part No. | Awg. Size | # Strands | # Leads | Outer Dia. inches | Outer Dia. mm | Wgt – lbs per 1000 ft | Wgt – kg per km |

|---|---|---|---|---|---|---|---|

| KD18AT02G | 18 | 7 | 2 | 0.301 | 7.65 | 36.40 | 54.17 |

| KD18AT03G | 18 | 7 | 3 | 0.318 | 8.08 | 49.72 | 74.00 |

| KD18AT04G | 18 | 7 | 4 | 0.348 | 8.84 | 63.46 | 94.44 |

| KD18AT05G | 18 | 7 | 5 | 0.384 | 9.75 | 79.77 | 118.72 |

| KD18AT06G | 18 | 7 | 6 | 0.420 | 10.67 | 93.75 | 139.52 |

| KD16AT02G | 16 | 7 | 2 | 0.325 | 8.26 | 45.69 | 68.00 |

| KD16AT03G | 16 | 7 | 3 | 0.345 | 8.76 | 63.32 | 94.24 |

| KD16AT04G | 16 | 7 | 4 | 0.378 | 9.60 | 81.41 | 121.16 |

| KD16AT05G | 16 | 7 | 5 | 0.417 | 10.59 | 102.10 | 151.95 |

| KD16AT06G | 16 | 7 | 6 | 0.476 | 12.09 | 126.75 | 188.63 |

| KD14AT02G | 14 | 7 | 2 | 0.413 | 10.49 | 70.78 | 105.34 |

| KD14AT03G | 14 | 7 | 3 | 0.454 | 11.53 | 104.31 | 155.24 |

| KD14AT04G | 14 | 7 | 4 | 0.51 | 12.85 | 136.82 | 203.62 |

| KD14AT05G | 14 | 7 | 5 | 0.57 | 14.53 | 175.06 | 260.53 |

| KD14AT06G | 14 | 7 | 6 | 0.63 | 15.88 | 205.80 | 306.28 |

| KD14AT07G | 14 | 7 | 7 | 0.63 | 15.88 | 221.18 | 331.50 |

| KD14AT12G | 14 | 7 | 12 | 0.81 | 20.68 | 376.63 | 560.51 |

| KD12CT02G | 12 | 19 | 2 | 0.47 | 11.84 | 97.73 | 145.45 |

| KD12CT03G | 12 | 19 | 3 | 0.50 | 12.67 | 138.61 | 206.28 |

| KD12CT04G | 12 | 19 | 4 | 0.56 | 14.15 | 182.47 | 271.56 |

| KD12CT05G | 12 | 19 | 5 | 0.62 | 15.72 | 228.69 | 340.34 |

| KD12CT06G | 12 | 19 | 6 | 0.66 | 16.79 | 261.07 | 388.53 |

| KD12CT12G | 12 | 19 | 12 | 0.89 | 22.50 | 499.27 | 743.03 |

| KD10CT02G | 10 | 19 | 2 | 0.52 | 13.16 | 132.78 | 197.61 |

| KD10CT03G | 10 | 19 | 3 | 0.56 | 14.17 | 190.70 | 283.81 |

| KD10CT04G | 10 | 19 | 4 | 0.62 | 15.65 | 248.59 | 369.96 |

| KD10CT05G | 10 | 19 | 5 | 0.67 | 16.89 | 301.29 | 448.39 |

| KD10CT06G | 10 | 19 | 6 | 0.73 | 18.64 | 359.41 | 534.89 |

| KDX3GT07G | 3/0 | 259 | 7 | 1.50 | 38.10 | 1156.00 | 1720.41 |

Standard conductor: Tinned Copper

Consult factory for alternative conductor and stranding options.