TLC 200

TEEMING LADLE CAR CABLE

Ratings/Approvals:

- 200°C – 600 Volts

- Passes the IEEE-383 Vertical Cable Tray Flame Test

- Passes NEMA WC 3 Flame Propagation Test

- RoHS Compliant

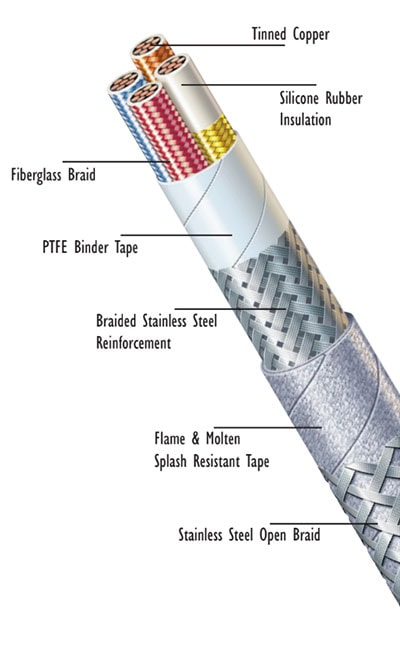

Construction:

- Conductors:

- 22 AWG – 2 AWG

- Annealed tinned copper

- Insulating System:

- Extruded silicone rubber with fiberglass braid cover over each insulated conductor. K-2 color code. (Unless specified)

- Binder Tapes:

- PTFE Fluoropolymer tape.

- Inner Reinforcement:

- Inner reinforcement of stainless steel braid.

- Overall Tapes:

- Flame and molten-splash resistant tape.

- Outer Covering:

- Outer stainless steel open braid reinforcement.

Characteristics:

- Silicone formulations suitable for UV, ozone, moisture exposure.

- Cable utilizes Radix “Torque Free” design. This eliminates memory found in traditional right hand or left hand twisted cables.

- Molten-splash tape provides extended flex life in splash environment.

- Suitable for applications to -60°C.

- Not recommended for outdoor use.

Applications:

- TLC 200 is constructed for use in high temperature applications as a multiple conductor control cable where resistance to abrasion,

- moisture, hot material spills and mechanical abuse are desired. This wire is used in steel plants, as teeming ladle transfer car cable.

- Flame and molten flash resistant tape extends cable life.

SPECIFICATIONS

TLC 200

TEEMING LADLE CAR CABLE

TLC 200 200C/600V

| Part Number | AWG Size | # Strands. | # Leads | Outer Dia. inches | Outer Dia. mm | Wgt – lbs per 1000 ft | Wgt – kg per km |

|---|---|---|---|---|---|---|---|

| KR14GT03S | 14 | 41 | 3 | 0.554 | 14.07 | 193.54 | 288.03 |

| KR14GT04S | 14 | 41 | 4 | 0.598 | 15.19 | 226.18 | 336.61 |

| KR14GT05S | 14 | 41 | 5 | 0.666 | 16.92 | 292.85 | 435.83 |

| KR14GT06S | 14 | 41 | 6 | 0.719 | 18.26 | 326.88 | 486.47 |

| KR12GT02S | 12 | 65 | 2 | 0.562 | 14.27 | 186.44 | 277.47 |

| KR12GT03S | 12 | 65 | 3 | 0.591 | 15.01 | 232.07 | 345.38 |

| KR12GT04S | 12 | 65 | 4 | 0.640 | 16.26 | 274.50 | 408.52 |

| KR12GT05S | 12 | 65 | 5 | 0.712 | 18.08 | 349.96 | 520.82 |

| KR12GT06S | 12 | 65 | 6 | 0.771 | 19.58 | 411.84 | 612.92 |

| KR10GT02S | 10 | 105 | 2 | 0.608 | 15.44 | 229.85 | 342.07 |

| KR10GT03S | 10 | 105 | 3 | 0.641 | 16.28 | 288.16 | 428.85 |

| KR10GT04S | 10 | 105 | 4 | 0.709 | 18.01 | 370.35 | 551.17 |

| KR10GT05S | 10 | 105 | 5 | 0.774 | 19.66 | 453.28 | 674.59 |

| KR10GT06S | 10 | 105 | 6 | 0.839 | 21.31 | 523.36 | 778.88 |

| KR08ET02S | 8 | 133 | 2 | 0.820 | 20.83 | 396.56 | 590.18 |

| KR08ET03S | 8 | 133 | 3 | 0.867 | 22.02 | 497.84 | 740.90 |

| KR08ET04S | 8 | 133 | 4 | 0.946 | 24.03 | 610.28 | 908.24 |

| KR08ET05S | 8 | 133 | 5 | 1.041 | 26.44 | 740.69 | 1102.32 |

| KR08ET06S | 8 | 133 | 6 | 1.136 | 28.85 | 865.83 | 1288.56 |

| KR06ET02S | 6 | 133 | 2 | 0.914 | 23.22 | 493.70 | 734.74 |

| KR06ET03S | 6 | 133 | 3 | 0.968 | 24.59 | 655.55 | 975.61 |

| KR06ET04S | 6 | 133 | 4 | 1.059 | 26.90 | 806.21 | 1199.83 |

| KR06ET05S | 6 | 133 | 5 | 1.168 | 29.67 | 980.65 | 1459.44 |

| KR06ET06S | 6 | 133 | 6 | 1.277 | 32.44 | 1136.60 | 1691.53 |

| KR04ET02S | 4 | 133 | 2 | 1.023 | 25.98 | 657.03 | 977.82 |

| KR04ET03S | 4 | 133 | 3 | 1.085 | 27.56 | 863.09 | 1284.48 |

| KR04ET04S | 4 | 133 | 4 | 1.190 | 30.23 | 1087.72 | 1618.78 |

| KR04ET05S | 4 | 133 | 5 | 1.315 | 33.40 | 1315.46 | 1957.72 |

| KR04ET06S | 4 | 133 | 6 | 1.440 | 36.58 | 1552.63 | 2310.68 |

Standard conductor: Tinned Copper

Optional Lead Construction: Composite extruded silicone rubber with intermediate fiberglass reinforcement (Sil-A-Blend®)

Consult factory for alternative conductor and stranding options.