FEP Insulated Tray Cable

UL Type TC-ER; C(UL)-CIC Cable

Ratings/Approvals:

- Meets Requirements of UL Standard 1277 “Standard for Tray Cable” Type TC-ER

- Meets Requirements of CSA Standard 22.2 No.239-09 “Control and Instrumentation Cable” Classified CIC

- Multi-Conductor Constructions Type FEP per UL 83

- 200°C Special Rated Applications

- 600V; 90°C Dry Rated General Use (UL)/ 200°C Dry Rated (CSA)

- Meets IEEE 1202/ FT4 Rating

- Meets UL “Oil Resistant I” Classification

- Compliant to ANSI/NFPA 70 (NEC) Article 336

- CSA compliance tested @90C for LTIR, Capacitance and Relative Permittivity per CSA standards 22.2 No. 75-14, and 22.2 No. 2556-15. Rated for use in environments requiring wet-rating.

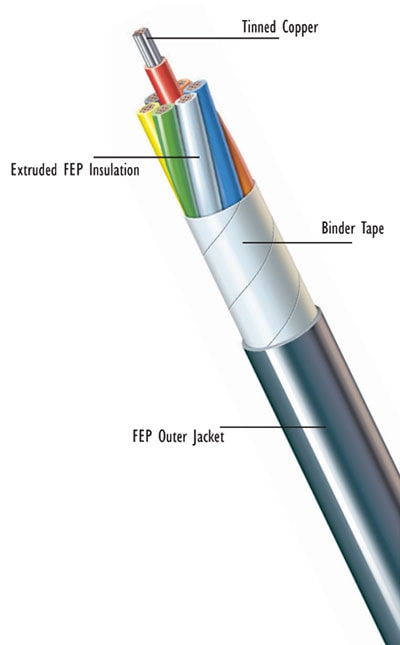

Construction:

- Conductors:

- 18 AWG – 2 AWG

- Solid or stranded coated annealed copper per ASTM B-33

- Insulating System:

- Extruded Flourinated Ethylene Propylene (FEP) per UL 83. Standard color is black, marked and numbered. (Colors available)

- Binder Tape:

- Nomex tape

- Shielding (Optional):

- Aluminum with poly-film backing. Coated copper drain wire.

- Jacketing:

- Extruded Fluorinated Ethylene Propylene (FEP). Standard color is black.

Characteristics:

- Excellent performance at temperature extremes

- High heat and weather resistance

- Excellent chemical and oil resistance

- Extruded FEP insulation available in colors

- FEP jacket material provides tough, low-friction protection

- Low flammability

SPECIFICATIONS

FEP Insulated Tray Cable

UL Type TC-ER; C(UL)-CIC Cable

Download FEP INSULATED TRAY CABLE Specs

FEP TRAY CABLE 200C/600V

| Part Number | AWG Size | # Cond. | Primary Mil- Wall | Core O.D. | Jacket Mil-Wall | Nominal OD | Wgt – lbs per 1000 ft |

|---|---|---|---|---|---|---|---|

| TS18AT02A | 18 | 2 | 0.020 | 0.140 | 0.045 | 0.245 | 52 |

| TS18AT03A | 18 | 3 | 0.020 | 0.186 | 0.045 | 0.291 | 67 |

| TS18AT04A | 18 | 4 | 0.020 | 0.207 | 0.045 | 0.312 | 80 |

| TS18AT05A | 18 | 5 | 0.020 | 0.220 | 0.045 | 0.325 | 93 |

| TS18AT07A | 18 | 7 | 0.020 | 0.257 | 0.045 | 0.362 | 117 |

| TS18AT09A | 18 | 9 | 0.020 | 0.295 | 0.045 | 0.400 | 144 |

| TS18AT12A | 18 | 12 | 0.020 | 0.341 | 0.045 | 0.446 | 180 |

| TS18AT16A | 18 | 16 | 0.020 | 0.394 | 0.045 | 0.499 | 226 |

| TS18AT19A | 18 | 19 | 0.020 | 0.429 | 0.060 | 0.564 | 282 |

| TS16AT02A | 16 | 2 | 0.020 | 0.160 | 0.045 | 0.265 | 62 |

| TS16AT03A | 16 | 3 | 0.020 | 0.212 | 0.045 | 0.317 | 81 |

| TS16AT04A | 16 | 4 | 0.020 | 0.236 | 0.045 | 0.341 | 99 |

| TS16AT05A | 16 | 5 | 0.020 | 0.251 | 0.045 | 0.356 | 116 |

| TS16AT07A | 16 | 7 | 0.020 | 0.393 | 0.045 | 0.498 | 148 |

| TS16AT09A | 16 | 9 | 0.020 | 0.337 | 0.045 | 0.442 | 233 |

| TS16AT12A | 16 | 12 | 0.020 | 0.388 | 0.060 | 0.523 | 321 |

| TS16AT16A | 16 | 16 | 0.020 | 0.449 | 0.060 | 0.584 | 365 |

| TS14AT02A | 14 | 2 | 0.020 | 0.216 | 0.045 | 0.321 | 75 |

| TS14AT03A | 14 | 3 | 0.020 | 0.233 | 0.045 | 0.338 | 99 |

| TS14AT04A | 14 | 4 | 0.020 | 0.260 | 0.045 | 0.365 | 121 |

| TS14AT05A | 14 | 5 | 0.020 | 0.292 | 0.045 | 0.397 | 143 |

| TS14AT07A | 14 | 7 | 0.020 | 0.324 | 0.045 | 0.429 | 184 |

| TS14AT09A | 14 | 9 | 0.020 | 0.391 | 0.045 | 0.496 | 230 |

| TS14AT12A | 14 | 12 | 0.020 | 0.449 | 0.060 | 0.584 | 318 |

| TS14AT16A | 14 | 16 | 0.020 | 0.508 | 0.060 | 0.643 | 401 |

| TS12CT02A | 12 | 2 | 0.020 | 0.254 | 0.045 | 0.359 | 92 |

| TS12CT03A | 12 | 3 | 0.020 | 0.274 | 0.045 | 0.379 | 123 |

| TS12CT04A | 12 | 4 | 0.020 | 0.306 | 0.045 | 0.411 | 152 |

| TS12CT05A | 12 | 5 | 0.020 | 0.343 | 0.045 | 0.448 | 182 |

| TS12CT07A | 12 | 7 | 0.020 | 0.381 | 0.045 | 0.486 | 237 |

| TS12CT09A | 12 | 9 | 0.020 | 0.460 | 0.060 | 0.595 | 323 |

| TS10CT02A | 10 | 2 | 0.020 | 0.296 | 0.045 | 0.401 | 121 |

| TS10CT03A | 10 | 3 | 0.020 | 0.320 | 0.045 | 0.425 | 162 |

| TS10CT04A | 10 | 4 | 0.020 | 0.357 | 0.045 | 0.462 | 203 |

| TS10CT05A | 10 | 5 | 0.020 | 0.400 | 0.045 | 0.505 | 245 |

| TS08GT02A | 8 | 2 | 0.030 | 0.452 | 0.060 | 0.587 | 234 |

| TS08GT03A | 8 | 3 | 0.030 | 0.488 | 0.060 | 0.623 | 390 |